Local Gas, Local Products

We crack POME biomethane using heat to create hydrogen and carbon black. Harnessed instead of wasted, used here at home.

Methane Pyrolysis

Hyjau uses thermal decomposition to split methane into hydrogen and solid carbon without burning it. No combustion, no waste, no CO₂.

Carbon Black for Malaysia

Industrial-grade carbon black for tires, inks and asphalt. A reliable local supply replacing Malaysia’s costly carbon black imports.

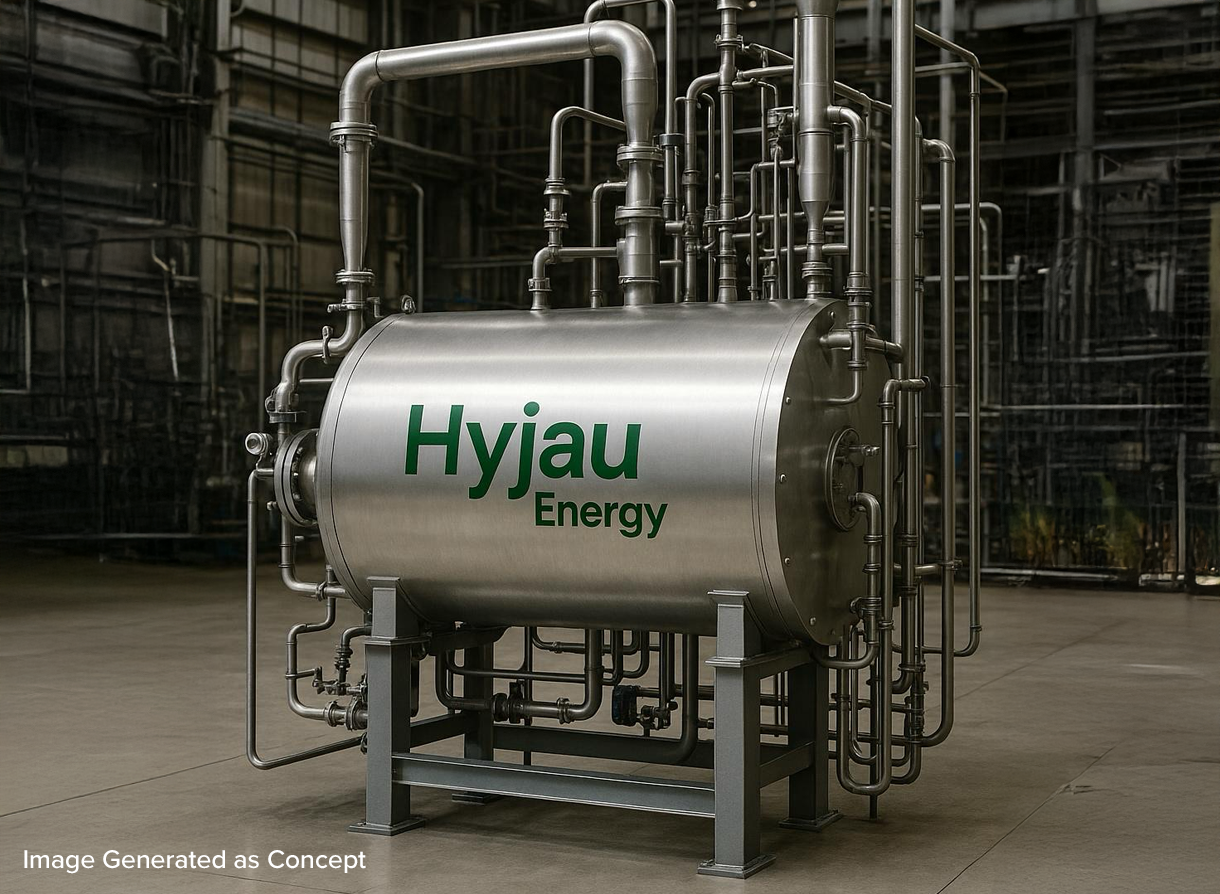

Malaysia’s First Methane Pyrolysis Reactor

Project Arus H2

Arus H2 is Hyjau’s pilot reactor and

Malaysia’s first step into methane

pyrolysis. Compact and modular, it’s

designed for deployment next to gas sources

with zero CO₂ emissions.

Each reactor delivers clean hydrogen for

energy and industrial-grade carbon black for

local markets. Engineered to serve

everything from palm oil mills and data

centres to national supply chains here at

home.

Hyjau is proudly working with a Malaysian

university to bring Arus H2 from lab to

field. This partnership anchors the know-how

here in Malaysia and ensures the technology

grows with local expertise.

Our Core Values

SAFE BY DESIGN

Every system is built to handle high heat and high pressure, keeping operations safe under the toughest Malaysian conditions.

MADE IN MALAYSIA

Hyjau uses locally sourced methane and turns it into products that strengthen Malaysia’s own industries and growing economy.

CARBON PRECISION

We don’t reduce emissions through offsets. We eliminate them through physical systems that split solid carbon from methane at the source.

NOTHING LEFT BEHIND

Our reactor converts methane into clean hydrogen and inert carbon black. No CO₂, no waste, no emissions.

Frequently Asked Questions

We build compact, modular methane

pyrolysis reactors here in Malaysia.

These systems take natural gas and

POME biomethane and convert them

into turquoise hydrogen and

industrial-grade carbon black with

no processed CO₂.

Our mission is to support Malaysia’s

ambitions to decarbonize heavy

industries as we grow our hydrogen

economy.

Green hydrogen requires 45–50 kWh of

electricity to make 1 kg of H₂.

Turquoise hydrogen only needs about

6–13 kWh to make 1 kg of H₂.

Blue hydrogen burns gas using coal

and then tries to capture the

released CO₂. With turquoise

hydrogen, we crack methane

indirectly with heat so there’s no

combustion, no CO₂ to chase and far

less energy consumed.

Malaysia’s palm oil mills release millions of tonnes of POME biomethane every year, usually wasted or flared. We use that biogas alongside local natural gas, so our reactors run on resources Malaysia already has available at a meaningful scale.

The carbon comes out as a solid black granular material. It is inert and harmless to the environment. We treat it as a valuable co-product, not a by-product: industrial-grade carbon black that Malaysia usually imports and uses in advanced materials for manufacturing, energy storage and infrastructure.

We use waste gas and natural gas found in Malaysia. We split it without producing CO₂. We create two valuable products with nothing left behind. No offsets. No imported feedstock. And we do it all here right at home.

Hyjau is designing and building its first reactor, Arus H2. We are at the testing stage for Arus H2 and moving fast, combining our expertise with support from a Malaysian university partner. Arus H2 is our proving ground: building the tech, adapting it to Malaysian conditions and scaling it into real supply chains.

Be Part of What's Next

Hyjau is building hydrogen and carbon systems from Malaysian resources.

We work with industry, researchers and policymakers who want solutions that can be tested, scaled and trusted. If that’s you, let’s talk.

Work with Hyjau